Lets first understand what is QRA and Monte Carlo?

Quantitative Risk Analysis (QRA) is a forecasting technique used to predict project cost and/or schedule outcomes, and to estimate an appropriate level of contingency. The QRA seeks to develop realistic project schedules and estimates for a genuine prediction on how the project may result. In the past, project contingency has often been set by means of an uplift (E.g. 10% on cost/time). This approach is rudimentary, often provides no justification on why a certain uplift is applied, and may result in an entirely inadequate risk contingency.

There is generally a finite number of occasions on which a project can baseline schedules/budgets; we can maximise our chances of success by utilising Monte Carlo Analysis (MC).

Monte Carlo is a mathematical technique utilising random sampling, within specified distributions to calculate the probability of explicit outcomes. The underlying principal of the method is rooted in the law of averages, and the law of large numbers; creating a mathematical prediction of how the process may eventuate.

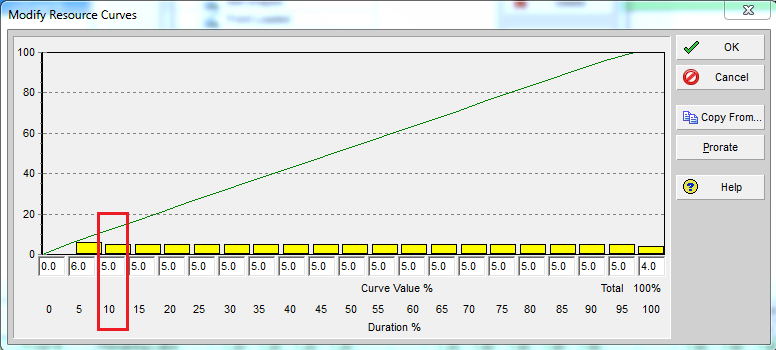

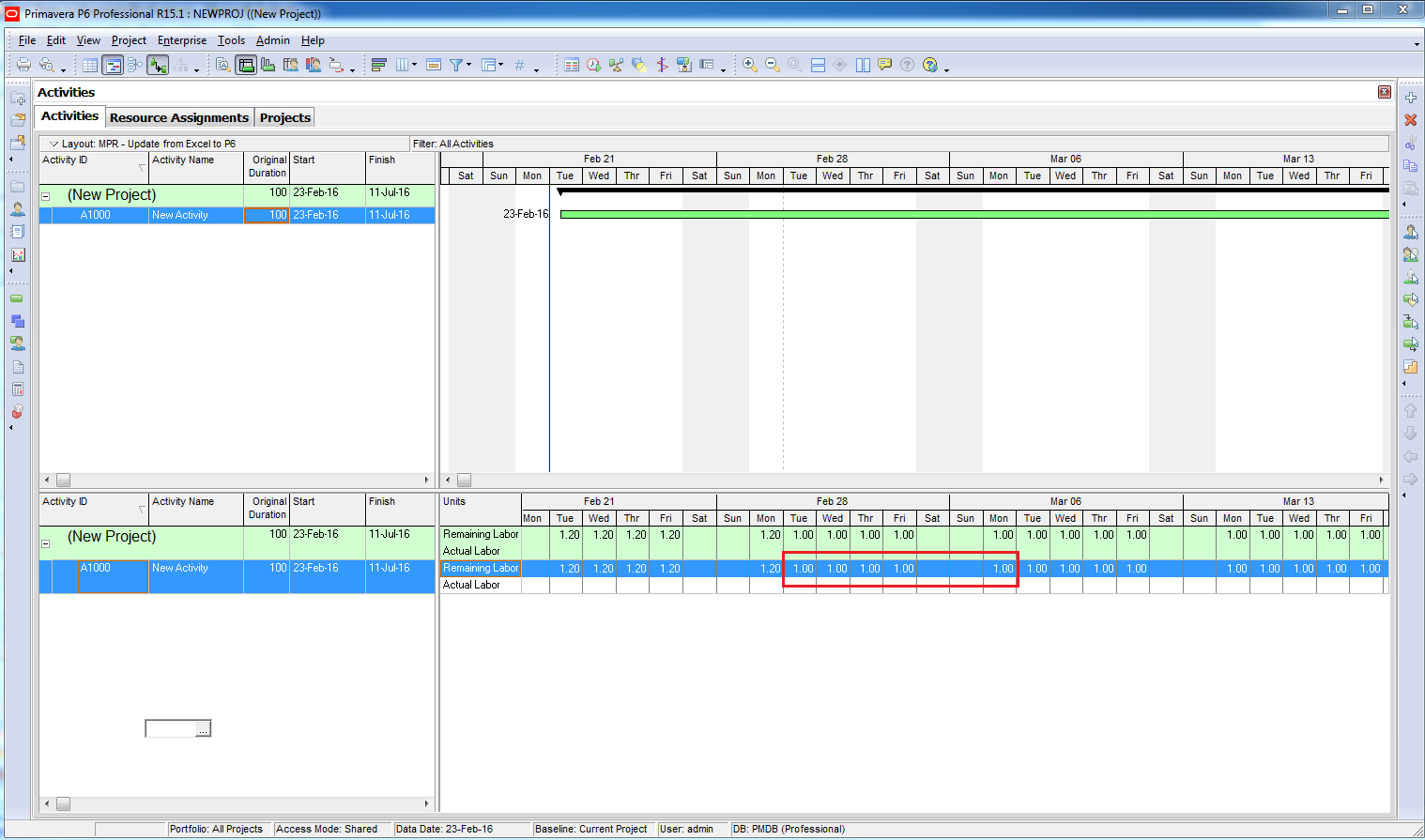

MC uses input duration ranges, as opposed to single point estimates for activity durations, to offset the inherent uncertainty in estimating. For a holistic coverage of possible cost/schedule outcomes, Risk Events (with a defined probability of occurrence, as well as an impact duration range) can be assigned to activities within the programme and contribute to the analysis (effectively extending the linked activity by the nominated impact duration value, on any iteration in which it appears). The Risk Analysis model is simulated hundreds, or thousands of times, and on each iteration a value is randomly selected from within the defined duration range for each activity. The most widely used, and easily understandable, range distribution is a triangular distribution (often referred to as a 3-point estimate and provided as a minimum, most likely, and maximum). The MC simulation is entirely random, plotting the outputs of each iteration as it works to create several useful insights. MC analysis undertaken on a project schedule takes cognisance of logic uncertainty and calendars, creating forward and backward pass calculations for each relationship in the plan, ultimately providing confidence intervals based on the range of start/finish dates for each milestone/activity.

Cumulative distribution graphs (S-curves) can be created to inform probability distributions (from which we can extrapolate confidence percentiles e.g. P50/P90.) For example, a P50 project completion date of 1st December 2018 occurs within the 50th percentile of the output dates; this means that in 50% of all iterations the project finish date is on, or before, 1st December 2018.

A relatively risk adverse organisation may prefer QRA models to provide a P90 confidence of meeting the schedule/cost target, where the results of the analysis show that in only 10% of iterations this value is exceeded. Conversely, a more risk tolerant organisation may be willing to accept a confidence percentile south of P50.

A QRA can help to provide a realistic forecast, and illustrate the key driving factors within a plan, in addition to quantifying the schedule benefits of timely interventions. This information is conducive to effective, risk-based decision making.

QSRA

The purpose of a Quantitative Schedule Risk Analysis (QSRA) is to provide assurance that key milestones/objectives within a project schedule will be met.

A QSRA can help to provide a realistic forecast, and illustrate the key driving factors within a plan, in addition to quantifying the schedule benefits of timely interventions. This information is conducive to effective, risk-based decision making.

The following inputs are necessary prior to analysis:

· Reviewed and agreed deterministic plan, considered suitable for analysis. If the existing project plan file is not suitable, a plan of

· Duration ranges for each line in the plan – minimum (optimistic), most likely (deterministic) and maximum (pessimistic). Depending on the Distribution type selected, a 2-point range (Min to Max) may be sufficient.

· Project Risk Register. (Note – there may be a requirement to hold a separate risk review prior to the QSRA process to ensure sufficiently mature Quantitative risk information is held)

Workshop – A workshop may be held with project stakeholders to review the analysis inputs. Several component parts of the analysis can be established at the workshop, such as risk impact mapping and duration uncertainty.

Programme – The programme must be representative of the programme of works, and must follow planning guidelines (attached). The programme should be reviewed in the workshop, to the following end:

- A review of activity durations to assign Duration Uncertainty values to the deterministic programme durations. The project team must ensure that the Duration Uncertainty estimates do not account for the impact of Risk and should account for only the inherent uncertainty in estimating the activity duration. The project team must challenge uncertainties and risks to ensure that optimism bias has been accounted for, and that all values provided are met with sufficient challenge.

- A review of where bespoke risks are to be mapped to the programme – This is to be an appropriate activity (or activities) the risk impact may be assigned.

Risk Register – The project risk register, with associated probability and impact values – including any planned management actions, must be addressed as it is a component part of the analysis. Existing risks should be sense checked by QSRA workshop attendees, and any links/correlation between risks should be identified before being imported into the plan. All risks should have assigned probability of occurrence values (%) as well as a Time impact ranges. The likely impact of a risk may be expressed as a 3 -point estimate (minimum, most likely, maximum) or a 2-point estimate (minimum to maximum).

QCRA

The purpose of a Quantitative Cost Risk Analysis (QCRA) is to estimate an appropriate level of cost contingency to supplement the project estimate and provide confidence that the budgetary allowance will not be surpassed.

A fully quantified risk register is essential to undertake the Cost Risk Analysis. Each applicable cost risk must have assigned probability of occurrence values (%) as well as a Cost impact ranges. The likely impact of a risk may be expressed as a 3 -point estimate (minimum, most likely, maximum) or a 2-point estimate (minimum to maximum).

The Risk Register should contain justification of the impact ranges (a qualifying statement of how costs have been built up, specific to each risk). E.g. ‘Cost impact may be X hours allowance for SME input @ £Xp/h + additional equipment costs = £Xk + Contractor prelims at £X per day ’.

The Risk Register should be cross-referenced with the Cost Model to ensure the impact of specific Risks have not been included for already in the base estimate.

QCRA should be run on Target (post-mitigated) risk assessment. This relies on the stability of the assumption, that identified mitigations are successful and the results are as expected.

A Monte Carlo Analysis can be run on the Risk Register inputs; resulting in the conception of output values specific to the project (as confidence percentiles). Specialist software (E.g @Risk, Primavera Risk Analysis etc. must be used to undertake the anlaysis).

Risks that are >70% of occurrence at Target assessment, should be transferred into the base estimate (or via contractual transfer depending on the project phase) or eliminated by terminating the linked activity/activities.

Cumulative distribution graphs (S-curves) can be created to inform probability distributions (from which we can extrapolate confidence percentiles e.g. P50/P90.)

If you like to know more about Project Risk Analysis or require any support, please contact us at info@Projcon-Advisory.com

International

International  Australia

Australia

Blogs

Blogs Glossary

Glossary Templates

Templates Videos

Videos Paperback Literature

Paperback Literature