· Project Plans which optimise expenditure of time, recognise cost implications and reflect the contractual obligations for the design, procurement, construction and commissioning of plant facilities.

· Regular updates of all project activities and their inter relationships.

· Early indication of deviations from the approved project programme so that action can be taken to minimise their effect.

It is to be noted that key elements of plans are Scope of work and Method of execution including WBS.

With regards to Scheduling, it is a determination of timing of events in the Project i.e., When tasks will be performed and its a reflection of plan. Here are main features of scheduling :

· Provides comparison of actual progress against plan

· Identify deviations from plan (problem areas)

· Enables early corrective actions and adjustments to plan

In other words, scheduling is the science of using mathematical calculations and logic to predict when and where work is to be carried out in an efficient and time-effective sequence.

Here are some rules to minimise the chances of your plan to get failed and ensure project completes before or on time.

Ø Most importantly, Project Planning & Scheduling must involve decisions concerning :

· the overall strategy of how the work process is to be broken down for control;

· how the control is to be managed;

· what methods are to be used for design, procurement & construction;

· the strategy for subcontracting and procurement;

· the interface between the various participants;

· the zones of operation and their interface;

· maximising efficiency of the project strategy with respect to cost and time;

· risk and opportunity management.

Ø In the process of converting the plan into a schedule the scheduler should determine:

· the duration of the activities;

· the party who will perform the activities;

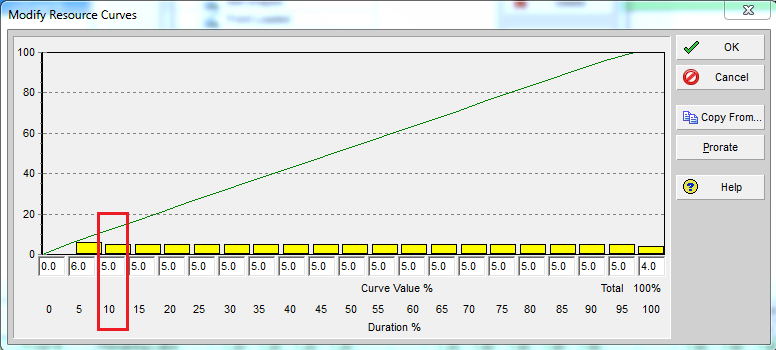

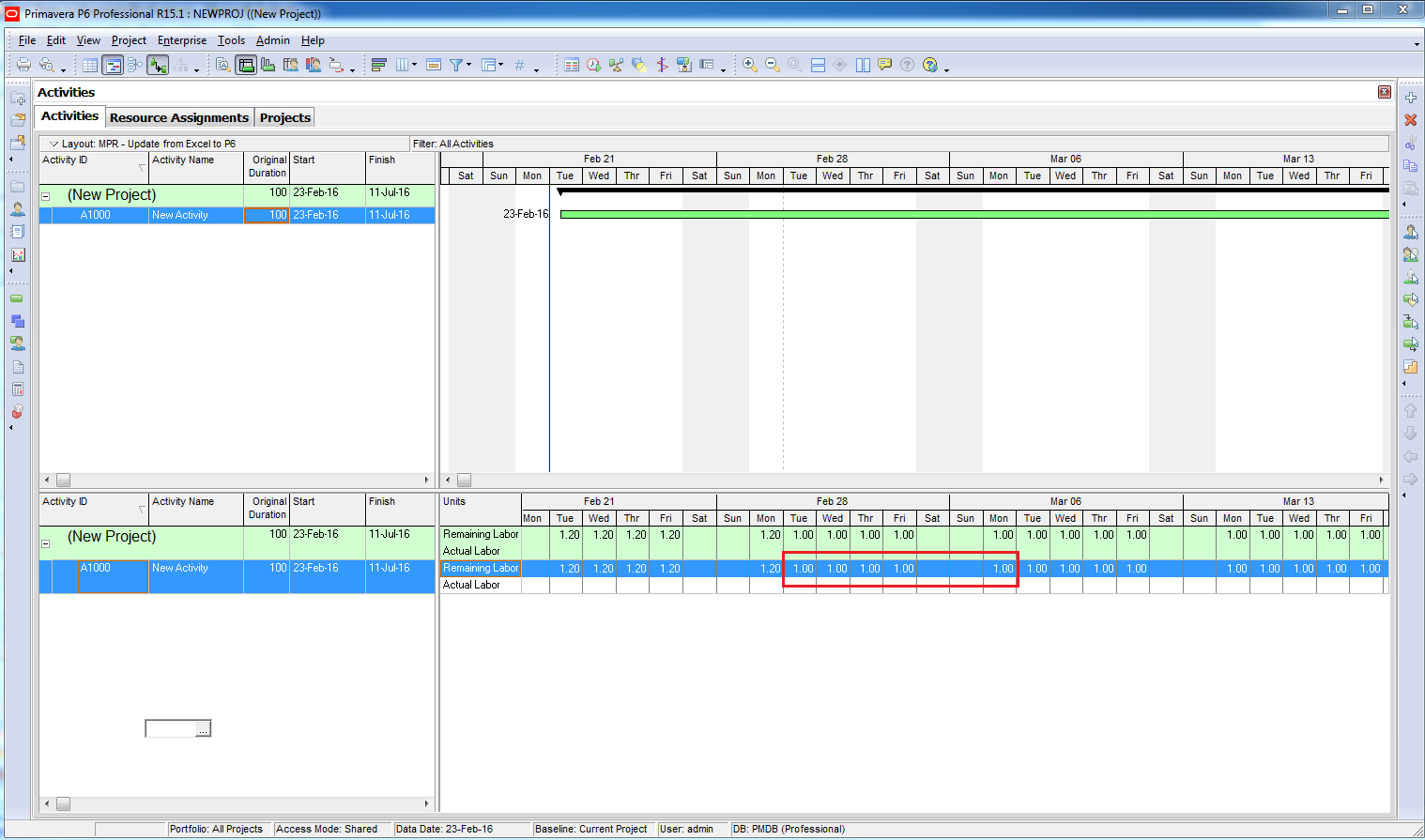

· the resources to be applied to the activities; and

· the method of sequencing of one, or more activities in relation to other activities.

Ø Depending upon the density of the schedule, the purpose for which it is to be used and the information available, an activity duration must be derived from following only. Any assumptions must be documented in case needs to be validated in future.

· experience

· industry standards

· benchmarking

· comparison with other projects

· calculation from resources

· specification.

Ø The schedule must illustrate a realistic and practical project plan showing how the project is intended to be, in a form that is sufficiently accurate for its identified density.

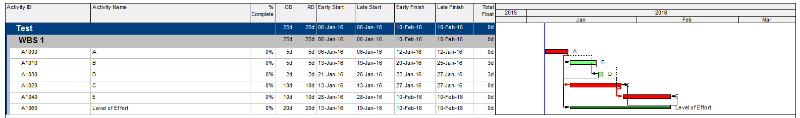

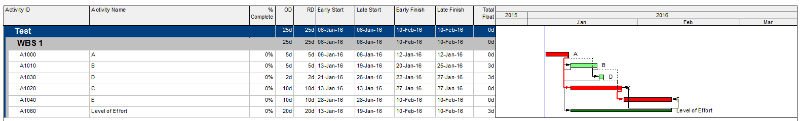

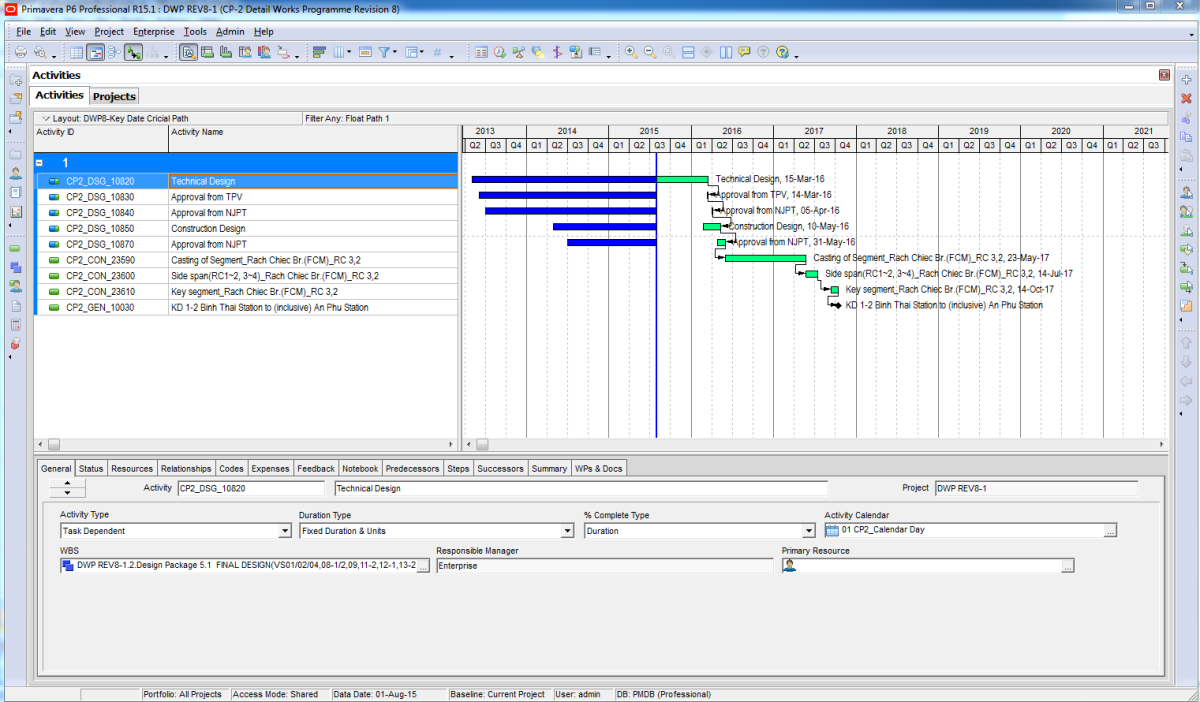

Ø Schedule must be capable of identifying the following:

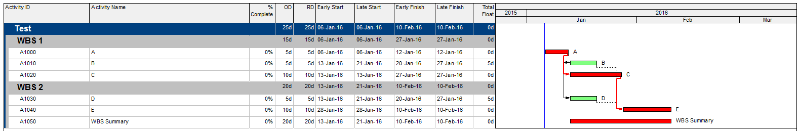

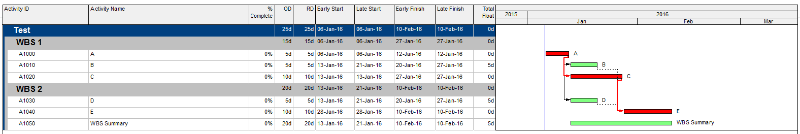

· the longest path to completion;

· the longest path to intermediate key dates, or sectional completion dates;

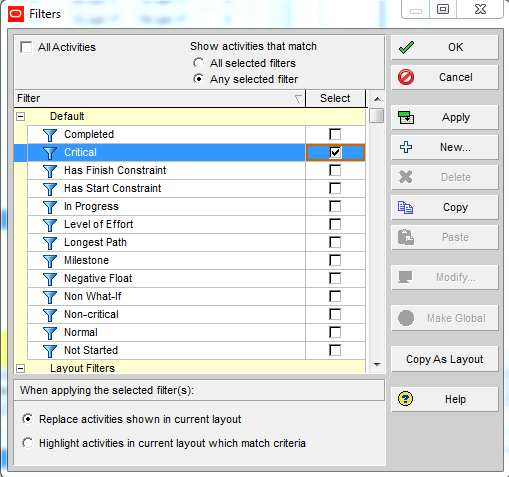

· logic and activities, which are critical from those, which are not critical to one, or more completion dates;

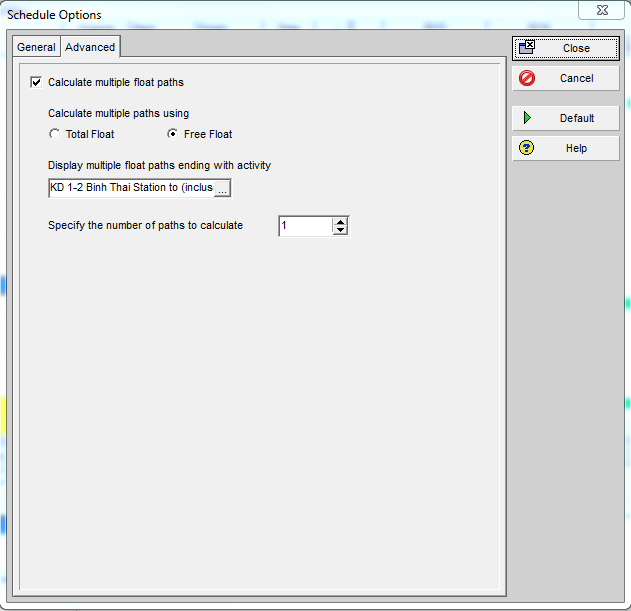

· total float on each path;

· free float on each activity, on each path;

Ø The strategy for schedule review must take account of the development of the schedule as better information becomes available and, as the project proceeds, the increasing density of the schedule as it develops from initiation through the work on site to commissioning the completed project.

Ø When change is imposed, scheduler must be able to identify it contemporaneously, the effect of delaying and disrupting causal events on the planned sequence and to advise team members on the likely effect of possible recovery strategies.

Ø Risk is inevitable part of any program however if dealt well, can be brought under control. Contingency period to deal with risks should be designed to be identified separately for both the employers and the contractors risks and for those risks which are related to:

· an activity, or chain of activities

· a contractor, subcontractor, supplier, or other resource

· an access, or egress date, or date of possession, or relinquishment of possession

· the works, any defined section, and any part of the works.

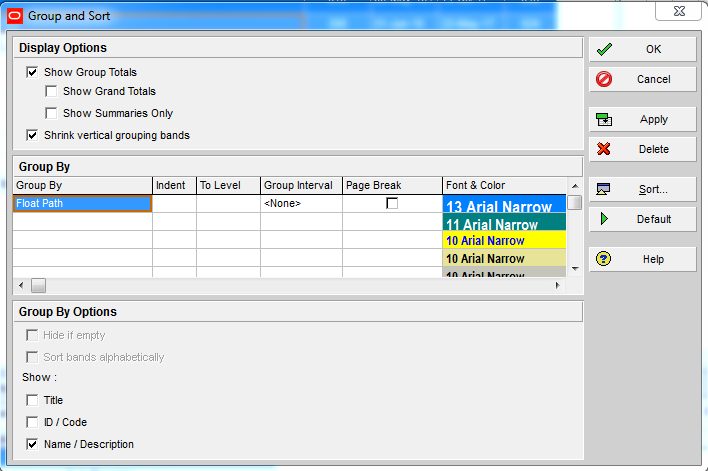

Ø For Schedule reporting , it is impracticable to use the whole of the schedule at any one time in its detail. For effective reporting it should be summarised to different degrees of summarisation for differing purposes. Most project scheduling software packages facilitate this hierarchical structuring by virtue of a summarisation, or roll-up facility.

Some basic tips:

- Do not use Mandatory Constrained dates. If a constraint has been used, then “Start on or After” can be opted. Keep use constraints as minimal as possible.

- Adopt Finish to Start logic as much as possible. Avoid SF links completely.

- No “Dangles” at all in schedule. LOE tasks could be an exception here.

- Avoid use of lags, especially long duration lags

- Keep Level 3 activities to similar levels of detail whenever possible

- Roll-ups from Level 3 to Level 2 must be “many to one” with no splitting of level 3 activities into individual level 2’s

- Status activities only after confirming its reliability & source

- Make your activity ID’s intelligent to identify where it belongs to.

- WBS development is must before the creation of schedule

- Avoid changing RD just to keep the activity out of critical path

- Identify Key Events and Drop Dead Times before developing the plan

- Schedules needs not to be way too detailed.

- Be realistic irrespective of pressure from Client, Project Managers and Engineering/Construction leads.

- Avoid “tweaking” of the logic to “make it fit.”

- Activities must be linear and sequential (Finish-to-Start), instead of being overlapped, i.e., successor starts before the predecessor – a version of “fast-tracking” at the molecular level.

- Planning procedure should encompass familiarisation, outline plan, strategic plan and detailed plan along with planning method statement

- Do not deceive (to mislead by a false appearance or statement). Don’t mislead the schedule by false appearance

- Get buy-in from the responsible owners of the plan. In absence of this, plan is no more than a worthless piece of paper.

- Ensure the calendars are set before developing the plan to includes the holidays and working hours restrictions, if any.

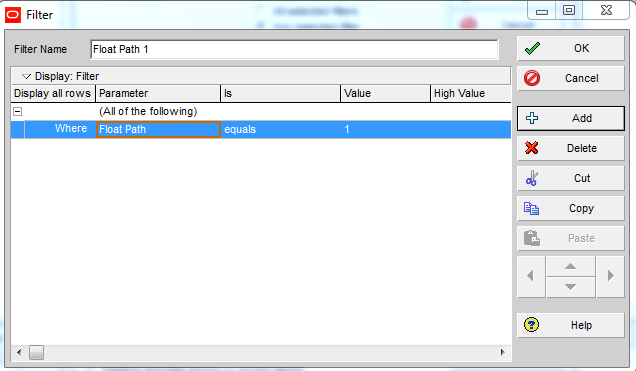

- Activity codes should identify the various attributes of the schedule as fields, the values of which will facilitate organisational changes, and facilitate filtering of important parts of the schedule.

- Schedule review must check for buildability, content, integrity, constraints, open end tasks, long lags, negative lags, ladders and critical paths to name a few.

Summary:

Don’t twist the plan, contort the plan, reduce the plan, expand the plan, modify the plan, distort the plan, adjust the plan, change the plan.. Instead, follow the plan..

Australia

Australia International

International

Blogs

Blogs Glossary

Glossary Templates

Templates Videos

Videos Paperback Literature

Paperback Literature